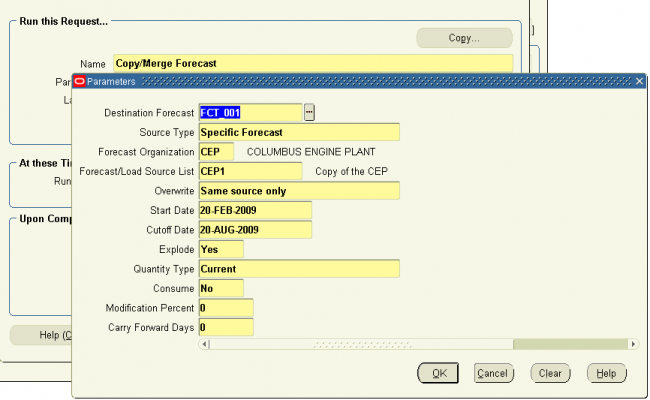

Copying/Merging Forecasts

You can copy forecasts from within your own organization, from any other organization, or from any focus or statistical forecast.

You can modify existing forecasts while merging them into new ones.

This allows you to forecast (for simulation purposes) the same collection of items, but with altered forecast rates and percentages, using a series of modification factors and/or carry forward days. When copying from existing forecasts, you have the option to copy original or current forecast quantities. When you merge a forecast, you can selectively overwrite the existing forecast, or you can consolidate forecasts by not overwriting previous forecast entries.

If you load source forecasts with one demand class into a destination forecast with a different demand class, Oracle Master Scheduling/MRP and Supply Chain Planning warns you that the demand classes are different. It associates the new entries in the destination forecast with the demand class of the destination forecast.

Usage of Copy/Merge : Production Forecasts

You can define and maintain forecasts for any item, at any level on your bills of material. You can forecast demand for products directly, or forecast product families and explode forecasts to individual products through planning bills. You can forecast demand for option classes, options, and mandatory components directly. You can also explode forecasts for models and option classes, through model and option class bills, to selected option classes, options, and mandatory components.

Forecasting Planning Bills

In Oracle Bills of Material, you can define multilevel planning bills, with multiple levels of planning items, to represent groups of related products that you want to forecast by family.

Typically, you can order components of a planning bill, but not the planning item itself.

The planning item is an artificial grouping of products that helps you to improve the accuracy of your forecasting since, generally, the higher the level of aggregation, the more accurate the forecast.

When you use the Load/Copy/Merge window to load a planning item forecast into another forecast, you can choose to explode the aggregate forecast for the planning item into detailed forecasts for each of the components defined on the planning bill. The forecast quantities exploded to the components are calculated by extending the planning item forecast by the component usages and planning percents defined on the planning bill. You can also choose to explode forecasts when you load a planning item forecast into a master schedule.

Forecasting Models

You can use the Bills of Material window in Oracle Bills of Material to define model and option class bills with multiple levels of option classes, options, and mandatory components to represent your complex configure-to-order products. You can then use forecast explosion to explode model and option class forecasts the same way you explode forecasts for planning items.

The logic for exploding models and option classes is the same as the logic used to explode planning items. You can choose to explode model and option class forecasts, just as you can choose to explode planning item forecasts when loading forecasts into other forecasts or master schedules.

Planning Models and Option Classes

Oracle Master Scheduling/MRP and Supply Chain Planning lets you master schedule any planned item on your master schedules, including models and option classes. With the twolevel master scheduling approach, you typically master schedule your key subassemblies your options and mandatory components since they are the highest level buildable items in your model bills.

Although models and option classes are not buildable items, you may want to master schedule them so that you can calculate available-to-promise (ATP) information for promising order ship dates by model or option class. You might also want to master schedule your models and option classes so that you can perform rough cut capacity checks by model and option class. This is particularly valid when different configurations of your models have very similar capacity requirements.

Note: Oracle Master Scheduling/MRP and Supply Chain Planning does not support planning for picktoorder models and option classes.

Good one....!!

Good one....!!